Index

Home

About

Blog

From: John De Armond

Newsgroups: rec.outdoors.rv-travel

Subject: Re: 12v vs 6v setup?

Date: Thu, 08 Apr 2004 23:11:46 -0400

Message-ID: <uosb70t9191l51fa7oaod8v4e2ctfk1q3j@4ax.com>

On Thu, 08 Apr 2004 16:56:14 -0700, Alan Balmer <albalmer@att.net> wrote:

>On Thu, 8 Apr 2004 13:27:13 -0700, "Dusty"

><rvliving@innerTRUCKlodge.com> wrote:

>

>>"Neon John" <johngdDONTYOUDARE@bellsouth.net> wrote in message

>>news:fs5b7099d0jurgg8vdu791ik8htghcuq61@4ax.com...

>>...

>>> work. If you decide to install a decent sized inverter or other heavy

>>> loads, the parallel 12 volt batteries will serve you better. The

>>> impedance of two batteries in parallel is much lower than 2 6 volts in

>>> series for about the same amp-hour capacity. That means the voltage

>>> varies less as loads are changed and during charging. Less light

>>> dimming and such.

>>Hey John, can you enlighten me a bit more here? This seems to fly in the

>>face of what I *understood* to be the case.

>

>You might try looking this subject up in the Google archives. I think

>you'll find that John is pretty much alone in his opinion of six volt

>batteries. Many of the rest of us are happily enjoying the increased

>capacity and have not seen the problems he describes.

Close your eyes, raise your arms over your head and repeat after me... "I

believe!!!" "And don't try to confuse me with facts either."

Once you drag out the instruments and do some actual measurements you can

reject the theology and base your beliefs at least a little bit on facts.

>

>> I was just about to buy 4-6's

>>and parallel two sets of 6's in series. They "should" act like a pair of

>>parallel 12's. I thought I'd run the numbers...but didn't come up with what

>>you described. Any embellishments would be most appreciated...

A DC model of a battery is a perfect voltage source (no voltage variation with

current) in series with a resistance. The resistance can be thought of as the

battery's deviation from perfection. The voltage drop across this resistance

linearly follows the current being withdrawn and causes the terminal voltage

to drop correspondingly. Obviously the internal impedance should be as low as

possible.

The impedance is affected by many design elements. Plate area, grid

thickness, interconnect cross-section, state of charge, degree of sulfation,

to name a few. There is no correlation at all between capacity in amp-hours

and internal impedance. A battery constructed of many fine grids attached to

the interconnectors with small gauge connections can have a very large

amp-hour capacity with a high impedance. The full amount of energy can be

withdrawn but only slowly. OTOH, the spiral wrapped AGM type battery with

only two continuous plates bonded along the whole length and with very heavy

cell interconnects can have a very low impedance AND a low capacity. A 10

amp-hour Hawker (formerly Gates) spiral wrapped cell can supply well over 1000

amps for a few seconds.

Some battery manufacturers quote an internal impedance value but even that

isn't accurate because the value changes with state of charge and with the age

of the battery. Indeed, some quite expensive "state of charge" meters use

this change in impedance to model the state of charge of the battery.

There really isn't much of a way to "run the numbers" unless you have

available something like the Spice model of that particular battery. The only

way to know the internal resistance is to measure it. There are expensive

meters that make the measurement directly but the old fashioned manual delta

method works just as well.

This involves measuring the battery terminal voltage at two different load

points and then computing the impedance with the equation deltaV/deltaA = Zi.

I use two well characterized resistors, one that draws about 10 amps and one

that draws about 50 amps, along with a current shunt. I use two DVMs, one to

measure the battery voltage and one to measure the shunt voltage. That gives

me the volts and amps at each load point. Simple number crunching gives the

internal impedance.

Using this setup I find that two Stowaway Group 29 12 volt, approx 110

amp-hour batteries in parallel exhibit a MUCH lower internal impedance than

two Stowaway 220 amp-hour golf cart batteries in series.

As an example consider the Stowaway golf cart batteries I have on my bench

right now, being used to test this new Vector smart charger. In their current

condition, about 4 years old, about 1 year of which was spent sitting on the

floor of my shop, when a 50 amp load is applied, the terminal voltage drops

from about 12.4 volts to 11.5, then drops slowly as the set discharges. My

log is in my RV across town but I seem to recall that this isn't a whole lot

worse than when they were new. This big initial drop causes the inverter to

trip from undervoltage far before the batteries are discharged. It also

causes the lights in the RV to dim under load and flare during charging.

When I apply about a similar load to my two Group 29s by turning on the

microwave oven which is powered from an inverter (about 65 amps), the voltage

drops from about 12.5 to about 12.3 and drops only very slowly with discharge.

Similarly, when I apply my Cordless Battery Charger (CBC) which is capable of

150 amp, to the fully discharged golf cart batteries, the terminal voltage

rises within a few minutes to the 14.8 volt (at 70 deg) end-of-bulk-charge

setpoint. Instead of being able to put around 70% of the full charge into the

battery at the 150 amp bulk charge rate as with my two Group 29s, I end up

putting all but a little bit of the charge in at the much lower absorption

rate which takes several hours. This defeats the very purpose of the smart

charger.

Parenthetically, I'll go out on a limb and postulate that Alan has never used

a charger capable of that rate and so would have no reason to be displeased. I

built my CBC with the express purpose of being able to fully charge my battery

bank in an hour or two. That lets me run the CBC for less than an hour a day

during my normal dry camping routine. The designers of the Xantrex, Onan and

other brands of high current intelligent chargers have similar goals, all

thwarted by the high impedance.

I have experimented with my line-operated MegaCharger (capable of 250 amps at

up to 20 volts) on these golf cart batteries. If I jack up the voltage

sufficient to keep the bulk rate in the 100-150 amp range, the batteries

charge about as fast as the Group 29s. But the terminal voltage rises to >16

volts. Not very nice to light bulbs and other 12 volt loads that would be

present in an RV.

With the two Group 29s in parallel (about 220 ah), my inverter runs the

microwave just fine even when the E-meter shows the remaining amp-hours to be

under 50 - in other words, practically fully discharged. My CBC will remain

in the bulk stage until about* 75-80% of the full charge has been returned.

Let me say here, before the question is asked, that I do not care what the

effects of fast charging or deep discharging might be on overall battery life.

Batteries are dirt cheap. I'm perfectly happy getting 2-3 years out of 'em.

I probably spend more on toilet paper over that period than I do on batteries.

I want to use the battery's capabilities to the maximum. I don't have room

for 500 ah of batteries and I don't stumble around under the glow of one

feeble LED at night to save power. I use my inverter to make coffee, fry

french fries and run the microwave. I have numerous 30 watt fluorescent

fixtures in the rig. I use a 12 volt electric blanket most of the time except

summer. I have white neon campsite lighting on the outside of my rig. In

other words, I flagrantly use electricity! If it takes draining the batteries

to >80% discharged, charging them at near 1C at the expense of a year or two's

life, to satisfy my needs then so be it. I don't want to bother other campers

any more than I have to so I designed the CBC to restore a day's typical use

in under an hour. I can run the CBC at mid-day when most people are doing

other things.

Someone might ask if my batteries might be oddballs. I've considered that.

This is the only set I've conducted such extensive testing on. But I can

observe that the terminal voltage of each 6 volt battery tracks the other

remarkably closely. That facts makes me comfortable in saying that I think

these are typical. If someone wanted to send me another set I'd be happy to

test 'em :-)

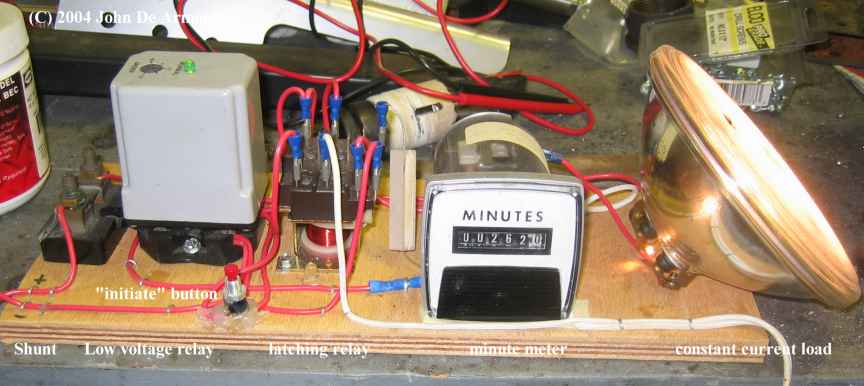

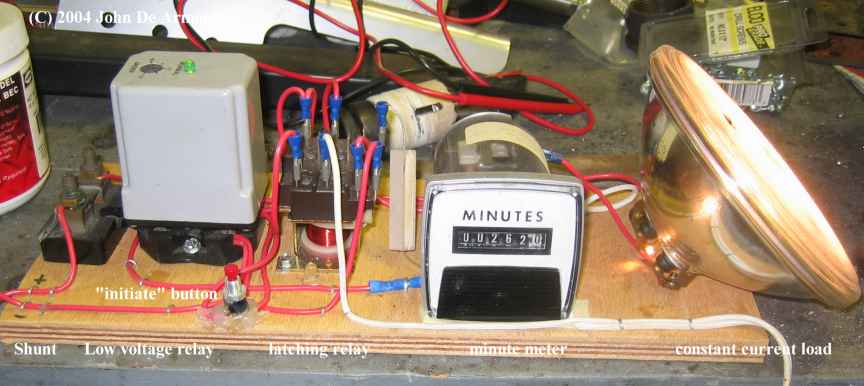

I'm currently running a capacity test on those two golf cart batteries. I

want to see how much capacity remains before I loose the new Vector's pulse

desulfator function on them. I use a simple homemade discharge tester to

measure the capacity. This tester discharges the battery at a fixed rate and

measure the elapsed time in minutes and seconds. Here is a photo of it.

The components are listed. The relay is an ordinary DPDT HVAC contactor out

of my junk box. It has a 24vac coil. The power resistor to the right of the

relay lets the coil live on 12 volts DC. It is wired to latch in through the

undervoltage relay when the red button is pressed. When the undervoltage

relay trips, the latch is released and the relay opens. This keeps the system

from cycling as the battery voltage recovers when the load is removed. The

relay is set for wet cells at 10.5 volts. All this stuff is hamfest fodder

that probably didn't cost me over $20.

Incandescent lamps are used as loads because they present a constant current

load over a fairly wide range of voltage. That 100 watt landing lamp draws

8.3 amps, varying less than 50 ma across the voltage range of interest.

The shunt lets me measure and verify the current draw. Normally when I'm

doing serious testing there is an E-meter hooked up to this tester to record

the actual amp-hours. For less stringent measurements, the current across the

shunt and the elapsed time let me compute the AH consumed with enough

accuracy.

I normally test at C/10 which is the rate that the capacity is normally

specified. I have a variety of lamps that I parallel until I get the desired

current. In this case I'm in the neighborhood of C/20 because a) I know these

batteries have a relatively high internal impedance and b) I didn't feel like

scrounging around in the bulb box :-)

So Dusty, warping back around to your original question, for your described

loads which are small, you'll get good service out of either setup. But if

you ever decide that you need to really thump your batteries then the parallel

12 volt setup will give better results. Another advantage of paralleled 12

volt batteries is that you can use an odd number and/or batteries of different

capacities. If you only have room for 3 batteries, that's fine. They'll live

together just fine.

John

* I'm using the term "about" because my logs are in my rig and not accessible

to me right now. Working from memory.

Index

Home

About

Blog